THE BASICS OF HARDWOOD FLOORING

There’s a lot to consider when choosing the right hardwood flooring for your home or project. Below you’ll find some of the topics we cover with every client that comes into our showroom. Hardness, grain pattern, durability and sustainability all play a part in the design and performance of your flooring.

OAK GRADING

CLEAR GRADE: A flooring product of mostly heartwood with a minimum number of character marks and discoloration, providing a uniform appearance while allowing for all heartwood natural color variations. Will admit the following: 3/8” (.3750”) (9.53 mm) wide bright sapwood entire length of the piece or equivalent if not more than 1” (25.4 mm) wide for 1/3 the length of piece; small burls and fine pin worm holes; and equivalent characters such as small tight checks; in the absence of these, one thin brown streak 3” (76.2 mm) long to be allowed every 6’ (1828.8 mm) of piece.

SELECT: A flooring product with coloration variations produced by differences of natural heartwood and sapwood, along with characters described.

The face may contain: unlimited sound sapwood; slight imperfections in milling; one (1) small tight knot every 3’ (914.4 mm) of piece; pin worm holes; burls and a reasonable amount of slightly open checks. Brown streaks should not extend the entire length of a piece. Two (2) flag worm holes to every 8’ (2438.4 mm) of the piece are permitted. Slight imperfections in face work (torn grain) admitted. An intermittent, brown machine burn across the face not exceeding 1/4” (.250”) (6.35 mm) in width admitted. Also, a slight quantity of bark on the back or sides admitted.Will admit pieces with onehalf (1/2) tongue, full length of the piece. Spot filling is generally required for open characters.

#1 COMMON: A flooring product which contains prominent variations in coloration and varying characters.

The following are not admitted: broken knots over 1/2” (.500”) (12.7 mm) in diameter, large grub worm holes; and splits extending through the piece. Open characters such as checks and knot holes are admitted, but must be sound and readily fill. Not more than 20” (508 mm) scant stock in thickness allowed to every 5’ (1524 mm) of length. Minor imperfections in machining permitted. Shall admit sticker stain; varying wood characteristics, such as flag worm holes, heavy streaks, checks, and worm holes; and an occasional dark machine burn across the face not exceeding 1/2” (.500”) (12.7 mm) wide, 1/64” (.0156”) (.40 mm) deep and not more than two (2) to every 3’ (914.4 mm) of length admitted. One-quarter (1/4) tongue, full length of the piece admitted. Extremely dark pieces are not to be included.

#2 COMMON: May contain sound natural variations of the forest product and manufacturing imperfections. The purpose of this grade is to furnish a floor suitable for

homes, general utility use, or where character marks and contrasting appearance is desired. The following are not admitted: shattered or rotten ends, large broken knots, excessive bad millwork, shake, advanced rot, and similar unsound defects. Dark machine burns exceeding 3/64” (.0469”) (1.19 mm) deep not admitted. Knot holes and open characters which will readily fill are admitted. Occasional scant thickness (hit or miss) on the back of the flooring board the entire length of the piece admitted, providing there is full bearing across the board at some point within three inches of the ends. A limited number of pieces with no tongue admitted

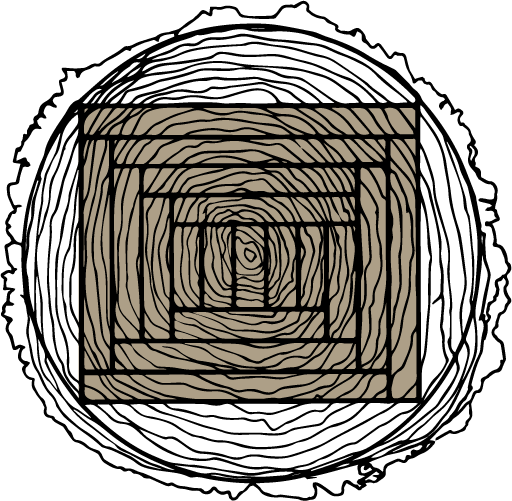

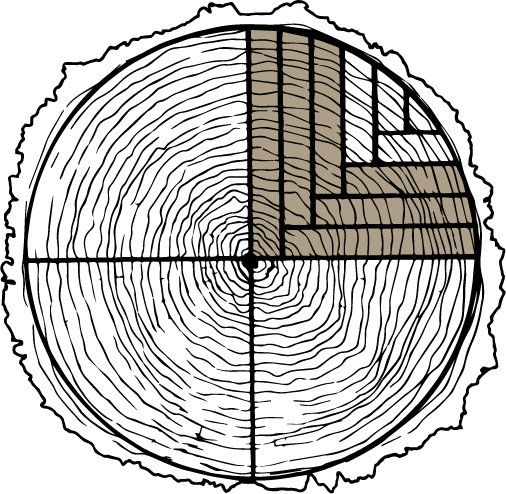

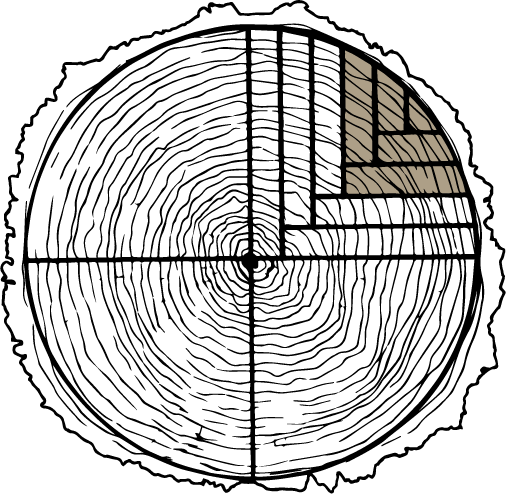

GRAIN PATTERN & CUTTING TECHNIQUE

Images and information courtesty of Graf Custom Hardwood

To produce plain sawn flooring, the log is passed through the blade cutting off plank after plank without changing the orientation of the blade or log. The resulting planks have different annual ring orientations when viewed from the end. The relative angle that form the rings and the surface go from almost zero degrees in the external planks to almost ninety degrees at log core. Cutting a log using the plain sawn method creates a cathedral grain pattern, and creates minimal waste.

Quarter sawn flooring is produced by quartering the log lengthwise, resulting in wedges with a right angle ending at approximately the center of the original log. Each quarter is then cut separately by tipping it up on its point and sawing boards successively along the axis. That results in boards with the annual rings mostly perpendicular to the faces. The “ray fleck,” “flake,” or “figure” of a quarter-sawn board is the medullary ray of the log, which emanates outward from the center of the log like spokes of a wheel.

Rift sawing is a technique of cutting boards from logs. Each board is cut along a radius of the original log, so that the saw cuts at right angles to the tree’s growth ring. This produces lumber of great stability. Rift characteristics as defined by NWFA-NOFMA are: in cross section the angle of the annual ring tangent to the face of the piece between 30 and 60 degrees. Grain lines are to be mostly parallel to the length of the pieces, and medullary ray flecks less than 1/16” (.0625”) (1.59 mm) wide.

Rift and quarter sawn flooring, refers to a mix of both rift sawn and quarter sawn boards, mixed together.

Rift boards and quartered boards share one characteristic - the growth rings manifest themselves on the face of the board as straight grain, with no visible cathedral grain or plain sawn look.

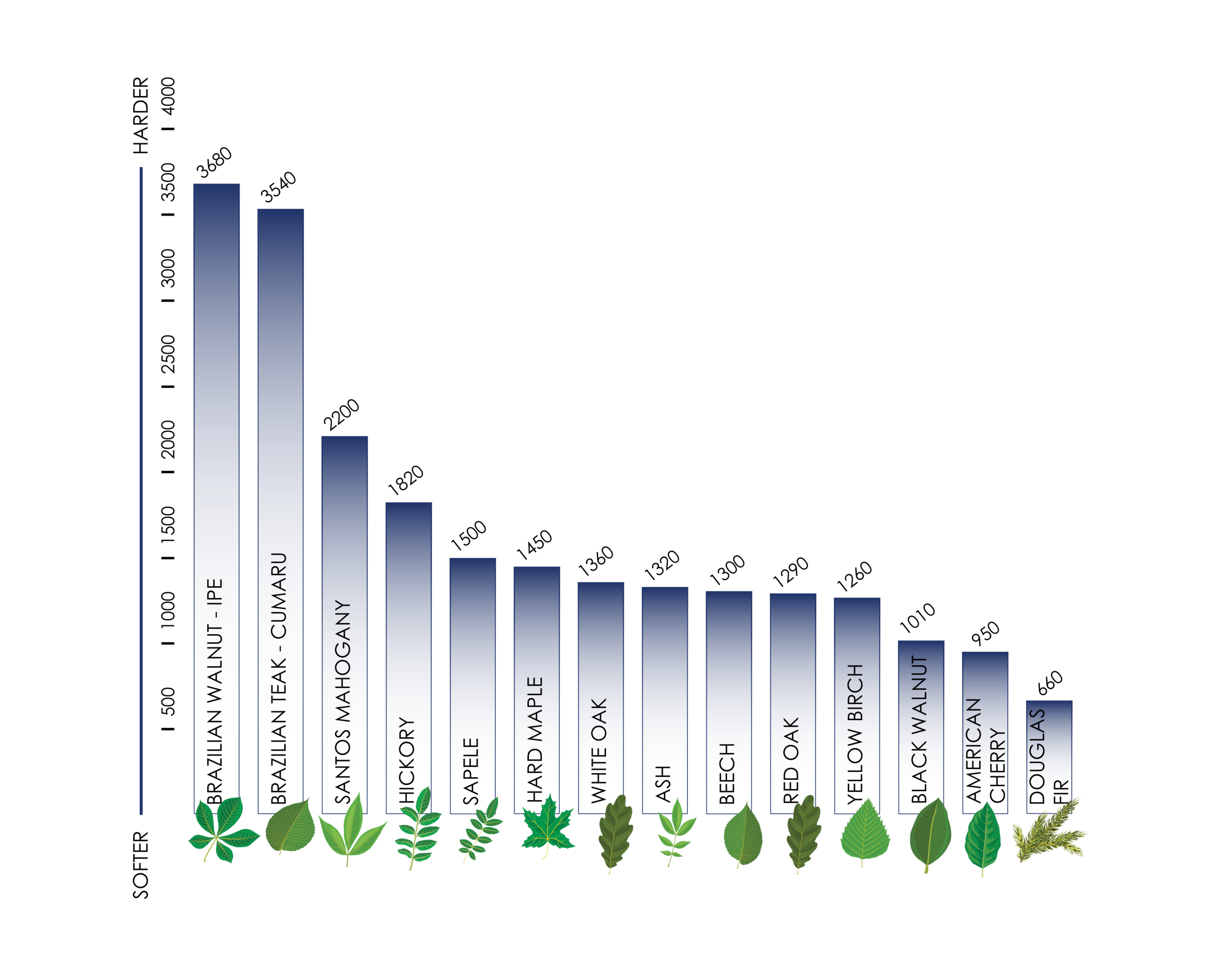

HARDWOOD FLOORS & DURABILITY

Each species of hardwood has a different level of hardness. Some common domestic species like walnut, cherry, and birch are less hard in comparison to other common domestic species like maple, hickory, and oak.

The Janka Scale gives a good indication of how well a wood species can be expected to withstand dents and dings. The scale is determined by the amount of pound-force required to push a .444-inch diameter steel ball halfway into the wood.Ratings for both domestic and imported species are included in the scale; however, none of these values apply to engineered wood flooring.

While Janka values give a general sense of how hard solid wood is, other factors also contribute to the durability of wood as well. This can include things like how the wood is cut, the dimensional stability and the finish that is applied to the wood.

All information is from the National Wood Flooring Association (NWFA)

DOMESTIC HARDWOOD & SUSTAINABILITY

By definition, “sustainable means to create and maintain conditions under which humans and nature can exist in productive harmony,” meeting today’s needs without compromising the ability of future generations to meet their needs. According to the U.S. Forest Service, there were 119 percent more hardwood trees in 2007 than in 1953, with the growth-to-removal ratio of 2.00 (two new trees for every one removed). So while it may take four to five decades for these new trees to mature, their wood will not be needed for another 50 to 100 years.

Few other countries can boast the success America has had in the sustainability of its hardwood forests. Due to the intensive application of Best Management Practices (BMP), the hardwood forests of America support a vibrant healthy stand of timber, as well as a large and diverse wildlife population, clean rivers and streams, and a host of recreational activities. The last 80 years of improved forest management and state and federal regulations, together with greater silvicultural understanding and public desire to conserve forests, have resulted in a dramatic recovery and renewal of the American hardwood resource.

Information is from the American Hardwood Information Center, and the American Hardwood Export Council

Hardwood Maintenance

Properly cleaning and maintaining your floors helps to insure that they will continue looking beautiful for many years to come. Routine maintenance includes sweeping with a soft bristle broom, vacuuming or dusting with a dry microfiber mop.

If you have a prefinished floor with beveled edges, vacuuming is the easiest way to remove dust and debris from between each board. Make sure that your vacuum does not have a beater bar, or that you can turn it off. Using a beater bar on hardwood floors will abrade the surface, causing premature wear. Clean the floors periodically with a professional wood floor cleaning product recommended by the flooring and/or finish manufacturer. If you’re unsure of what kind of product to use, contact your flooring contractor.

Do not use vinyl or tile cleaning products on wood floors. Self-polishing acrylic waxes cause woodto become slippery and appear dull quickly.

Use throw rugs at doorways to help prevent debris from being tracked in and scratching the floor.

Do not wet-mop or steam mop a wood floor. Water and steam can dull the finish and evendamage the wood.

Wipe up spills immediately with a slightly dampened cloth.

Put stick-on felt protectors under the legs of furniture to prevent scuffing and scratching. Replacethese often as dirt and debris can become imbedded on the pad and act like sand paper on theflooring surface.

Avoid walking on your wood floors with sports cleats and high heels in disrepair. A 125-poundwoman walking in high heels with an exposed heel nail can exert up to 8,000 pounds per squareinch. This kind of impact can dent any floor surface.

Do not slide furniture across your wood floor. Pick up the furniture to move it and to preventscratches.

For wood flooring in the kitchen, place an area rug at the kitchen sink.

Use a humidifier throughout the winter months to minimize gaps.

Recommended Maintenance Schedule

Daily Sweep or dust mop

Weekly Vacuum using the bare floor setting

Monthly Clean with recommended wood flooring cleaner

Every 3 - 5 Years Maintenance coat Every Few Decades Sand and refinish